產(chǎn)品中心

珀金斯Perkins2206D-E13TA操作保養(yǎng)

詳細描述

Operation and

Maintenance

Manual

2206D-E13TA Industrial Engine

Engine Operation

Interrupted starts put excessive stress on the drive

train. Interrupted starts also waste fuel. To get the

driven equipment in motion, engage the clutch

smoothly with no load on the equipment. This

method should produce a start that is smooth and

easy. The engine rpm should not increase and the

clutch should not slip.

i06219260

Engine Operation

3. Ensure that the ranges of the gauges are normal

when the engine is operating at one-half of the

rated rpm. Ensure that all gauges operate properly.

Correct operation and maintenance are key factors in

obtaining the maximum life and economy of the

engine. If the directions in the Operation and

Maintenance Manual are followed, costs can be

4. Increase the engine rpm to the rated rpm. Always

increase the engine rpm to the rated rpm before

the load is applied.

minimized and engine service life can be maximized.

Variable Speed Engine

The engine can be operated at the rated rpm after the

engine reaches operating temperature. The engine

will reach normal operating temperature sooner

during a low engine speed (rpm) and during a low-

power demand. This procedure is more effective than

idling the engine at no load. The engine should reach

operating temperature in a few minutes.

5. Apply the load. Begin operating the engine at low

load. Check the gauges and equipment for proper

operation. After normal oil pressure is reached and

the temperature gauge begins to move, the engine

may be operated at full load. Check the gauges

and equipment frequently when the engine is

operated under load.

Gauge readings should be observed and the data

should be recorded frequently while the engine is

operating. Comparing the data over time will help to

determine normal readings for each gauge.

Extended operation at low idle or at reduced load

may cause increased oil consumption and carbon

buildup in the cylinders. This carbon buildup

Comparing data over time will also help detect

abnormal operating developments. Significant

changes in the readings should be investigated.

results in a loss of power and/or poor performance.

i04018232

Constant Speed Engine

Fuel Conservation Practices

Allow the engine to warn up before applying load.

Gauge readings should be observed and the data

should be recorded frequently while the engine is

operating. Comparing the data over time will help to

determine normal readings for each gauge.

Comparing data over time will also help detect

abnormal operating developments. Significant

changes in the readings should be investigated.

The efficiency of the engine can affect the fuel

economy. Perkins design and technology in

manufacturing provides maximum fuel efficiency in all

applications. Follow the recommended procedures in

order to attain optimum performance for the life of the

engine.

• Avoid spilling fuel.

i04038637

Engaging the Driven

Equipment

Fuel expands when the fuel is warmed up. The fuel

may overflow from the fuel tank. Inspect fuel lines for

leaks. Repair the fuel lines, as needed.

• Be aware of the properties of the different fuels.

Use only the recommended fuels. Refer to the

Operations and Maintenance Manual, “Fuel

Recommendations”for further information.

1. Operate the engine at one-half of the rated rpm,

when possible.

• Avoid unnecessary idling.

2. Engage the driven equipment without a load on the

equipment, when possible.

Shut off the engine rather than idle for long periods of

time.

This document has been printed from SPI2. NOT FOR RESALE

![]()

SEBU9072

35

Engine Operation

Fuel Conservation Practices

• Observe the service indicator frequently. Keep the

air cleaner elements clean.

• Ensure that the turbocharger is operating correctly.

For more information refer to this Operation and

Maintenance Manual, “Turbocharger - Inspect”

• Maintain a good electrical system.

One faulty battery cell will overwork the alternator.

This fault will consume excess power and excess

fuel.

• The belt should be in good condition. Refer to the

Systems Operation, Testing and Adjusting, “V-Belt

Test” for further information.

• Ensure that all of the connections of the hoses are

tight. The connections should not leak.

• Ensure that the driven equipment is in good

working order.

• Cold engines consume excess fuel. Utilize heat

from the jacket water system and the exhaust

system, when possible. Keep cooling system

components clean and keep cooling system

components in good repair. Never operate the

engine without water temperature regulators. All of

these items will help maintain operating

temperatures.

This document has been printed from SPI2. NOT FOR RESALE

![]()

36

SEBU9072

Cold Weather Operation

Radiator Restrictions

Cold Weather Operation

The cloud point of the fuel is the temperature at which

waxes naturally found in the diesel fuel begin to form

crystals. The cloud point of the fuel must be below

lowest ambient temperature to prevent filters from

plugging.

i05954317

Radiator Restrictions

Cold Filter Plugging Point is a temperature at which a

particular fuel will pass through a standardized

filtration device. This CFPP gives an estimate of the

lower operability temperature of fuel

Perkins discourages the use of airflow restriction

devices that are mounted in front of radiators. Airflow

restriction can cause the following conditions:

Pour point is the last temperature before the fuel flow

stops and waxing of the fuel will start.

• High exhaust temperatures

• Power loss

Be aware of these properties when diesel fuel is

purchased. Consider the average ambient air

temperature for the engines application. Engines that

are fueled in one climate may not operate well if the

engines are shipped to colder climate. Problems can

result due to changes in temperature.

• Excessive fan usage

• Reduction in fuel economy

If an airflow restriction device must be used, the

device should have a permanent opening directly in

line with the fan hub. The device must have a

Before troubleshooting for low power or for poor

performance in the winter, check the fuel for waxing

minimum opening dimension of at least 770 cm

(120 in

2

The following components can provide a means of

minimizing fuel waxing problems in cold weather:

2

).

A centered opening that is directly in line with the fan

hub is specified in order to prevent an interrupted

airflow on the fan blades. Interrupted airflow on the

fan blades could cause a fan failure.

• Fuel heaters, which may be an OEM option

• Fuel line insulation, which may be an OEM option

Winter and arctic grades of diesel fuel are available in

the countries and territories with severe winters. For

more information refer to the Operation and

Maintenance Manual, “Fuel For Cold Weather

Operation”

Perkins recommends a warning device for the inlet

manifold temperature and/or the installation of an inlet

air temperature gauge. The warning device for the

inlet manifold temperature should be set at 75 °C

(167 °F). The inlet manifold air temperature should

not exceed 75 °C (167 °F). Temperatures that

exceed this limit can cause power loss and potential

engine damage.

Another important fuel property which can affect cold

start and operation of diesel engine is Cetane

number. Detail and requirements of this property are

given in this Operation and Maintenance Manual,

“Fluid Recommendations”.

i05849931

Fuel and the Effect from Cold

Weather

i06093465

Fuel Related Components in

Cold Weather

Note: Only use grades of fuel that are recommended

by Perkins. Refer to this Operation and Maintenance

Manual, “Fluid Recommendations”.

Fuel Tanks

Properties of the diesel fuel can have a significant

effect on the engine cold start capability. It is critical

that the low temperature properties of diesel fuel are

acceptable for the minimum ambient temperature the

engine is expected to see in the operation.

Condensation can form in partially filled fuel tanks.

Top off the fuel tanks after operating the engine.

Fuel tanks should contain some provision for draining

water and sediment from the bottom of the tanks.

Some fuel tanks use supply pipes that allow water

and sediment to settle below the end of the fuel

supply pipe.

Following properties are used to define fuels low

temperature capability:

• Cloud point

Some fuel tanks use supply lines that take fuel

directly from the bottom of the tank. If the engine is

equipped with this system, regular maintenance of

the fuel system filter is important.

• Pour point

• Cold Filter Plugging Point (CFPP)

This document has been printed from SPI2. NOT FOR RESALE

![]()

SEBU9072

37

Cold Weather Operation

Fuel Related Components in Cold Weather

Drain the water and sediment from any fuel storage

tank at the following intervals:

• Weekly

• Oil changes

• Refueling of the fuel tank

This draining will help prevent water and/or sediment

from being pumped from the fuel storage tank and

into the engine fuel tank.

Fuel Heaters

Fuel heaters help to prevent fuel filters from plugging

in cold weather due to waxing. A fuel heater should

be installed in order for the fuel to be heated before

the fuel enters the primary fuel filter.

Select a fuel heater that is mechanically simple, yet

adequate for the application. The fuel heater should

also help to prevent overheating of the fuel. High fuel

temperatures reduce engine performance and the

availability of engine power. Choose a fuel heater with

a large heating surface. The fuel heater should be

practical in size. Small heaters can be too hot due to

the limited surface area.

Disconnect the fuel heater in warm weather.

Note: Fuel heaters that are controlled by the water

temperature regulator or self-regulating fuel heaters

should be used with this engine. Fuel heaters that are

not controlled by the water temperature regulator can

heat the fuel in excess of 65° C (149° F). A loss of

engine power can occur if the fuel supply temperature

exceeds 37° C (100° F).

Note: Heat exchanger type fuel heaters should have

a bypass provision in order to prevent overheating of

the fuel in warm-weather operation.

For further information on fuel heaters, consult your

Perkins distributor.

This document has been printed from SPI2. NOT FOR RESALE

![]()

38

SEBU9072

Engine Stopping

Stopping the Engine

Engine Stopping

1. Remove the load from the engine so that the

engine has no more than 30% power.

i02334873

2. Run the engine at the programmed low idle speed

for at least 3 minutes.

Stopping the Engine

3. After the cool down period, turn the start switch to

the OFF position.

NOTICE

i01465494

Stopping the engine immediately after it has been

working under load, can result in overheating and ac-

celerated wear of the engine components.

After Stopping Engine

Avoid accelerating the engine prior to shutting it

down.

Note: Before you check the engine oil, do not operate

the engine for at least 10 minutes in order to allow the

engine oil to return to the oil pan.

Avoiding hot engine shutdowns will maximize turbo-

charger shaft and bearing life.

• Check the crankcase oil level. Maintain the oil level

between the “ADD” mark and the “FULL” mark

on the oil level gauge.

Note: Individual applications will have different

control systems. Ensure that the shutoff procedures

are understood. Use the following general guidelines

in order to stop the engine.

• If necessary, perform minor adjustments. Repair

any leaks and tighten any loose bolts.

1. Remove the load from the engine. Reduce the

engine speed (rpm) to low idle. Allow the engine to

idle for five minutes in order to cool the engine.

• Note the service hour meter reading. Perform the

maintenance that is in the Operation and

Maintenance Manual, “Maintenance Interval

Schedule”.

2. Stop the engine after the cool down period

according to the shutoff system on the engine and

turn the ignition key switch to the OFF position. If

necessary, refer to the instructions that are

provided by the OEM.

• Fill the fuel tank in order to help prevent

accumulation of moisture in the fuel. Do not overfill

the fuel tank.

NOTICE

Only use antifreeze/coolant mixtures recommended

in the Coolant Specifications that are in the Operation

and Maintenance Manual. Failure to do so can cause

engine damage.

i05812522

Manual Stop Procedure

• Allow the engine to cool. Check the coolant level.

NOTICE

Stopping the engine immediately after it has been

working under load can result in overheating and ac-

celerated wear of the engine components.

• If freezing temperatures are expected, check the

coolant for proper antifreeze protection. The

cooling system must be protected against freezing

to the lowest expected outside temperature. Add

the proper coolant/water mixture, if necessary.

If the engine has been operating at high rpm and/or

high loads, run at low idle for at least three minutes to

reduce and stabilize internal engine temperature be-

fore stopping the engine.

• Perform all required periodic maintenance on all

driven equipment. This maintenance is outlined in

the instructions from the OEM.

Avoiding hot engine shutdowns will maximize turbo-

charger shaft and bearing life.

Note: Individual applications have different control

systems. Ensure that the shutoff procedures are

understood. Use the following general guidelines in

order to stop the engine.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9072

39

Maintenance Section

Refill Capacities

Maintenance Section

Refill Capacities

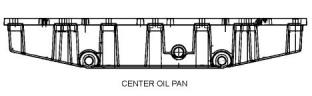

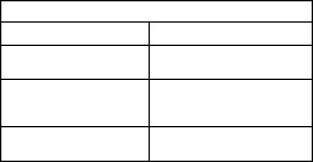

Table 2

2206 Industrial Engine

Approximate Refill Capacities

Oil Sump(1)

Liters

32 L

Quarts

33.8 qt

39.1 qt

31.7 qt

Standard Oil Pan

Deep Oil Pan

i06093491

37 L

Refill Capacities

Center Oil Pan

30 L

(1)

These values are approximate capacities for the crankcase oil

sump which include the standard oil filters that are installed at

the factory. Engines with auxiliary oil filters will require additional

oil. Refer to the OEM specifications for the capacity of the auxili-

ary oil filter.

Refer to this Operation and Maintenance Manual,

“Fluid Recommendations” for information about the

fluids which are acceptable for this engine.

Lubricant Refill Capacity

The refill capacities for the engine crankcase reflect

the approximate capacity of the crankcase or sump

plus standard oil filters. Auxiliary oil filter systems will

require additional oil. Refer to the OEM specifications

for the capacity of the auxiliary oil filter.

Coolant Refill Capacity

To maintain the cooling system, the total cooling

system capacity must be known. The capacity of the

total cooling system will vary. The capacity will

depend on the size of the radiator (capacity). Table 3

should be completed by the customer for the

maintenance of the cooling system.

Table 3

Approximate Capacity of the Cooling System

Compartment or

System

Liters

Quarts

Total Cooling System

(1)

(1)

The total cooling system capacity includes the following compo-

nents:the engine block, the radiator and all coolant hoses and

lines.

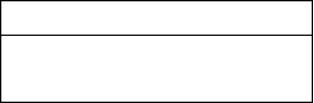

Illustration 22

g02293575

Standard and deep oil pans

i06194716

Fluid Recommendations

General Coolant Information

NOTICE

Never add coolant to an overheated engine. Engine

damage could result. Allow the engine to cool first.

Illustration 23

g02289293

Center oil pan

NOTICE

If the engine is to be stored in, or shipped to an area

with below freezing temperatures, the cooling system

must be either protected to the lowest outside temper-

ature or drained completely to prevent damage.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

40

SEBU9072

Refill Capacities

Fluid Recommendations

For a water analysis, consult one of the following

NOTICE

Frequently check the specific gravity of the coolant for

proper freeze protection or for anti-boil protection.

sources:

• Local water utility company

• Agricultural agent

• Independent laboratory

Clean the cooling system for the following reasons:

• Contamination of the cooling system

• Overheating of the engine

Additives

Additives help to protect the metal surfaces of the

cooling system. A lack of coolant additives or

insufficient amounts of additives enable the following

conditions to occur:

• Foaming of the coolant

NOTICE

Never operate an engine without water temperature

regulators in the cooling system. Water temperature

regulators help to maintain the engine coolant at the

proper operating temperature. Cooling system prob-

• Corrosion

• Formation of mineral deposits

• Rust

lems

can

develop

without

water

temperature

regulators.

• Scale

Many engine failures are related to the cooling

system. The following problems are related to cooling

system failures: Overheating, leakage of the water

pump and plugged radiators or heat exchangers.

• Foaming of the coolant

Many additives are depleted during engine operation.

These additives must be replaced periodically.

These failures can be avoided with correct cooling

system maintenance. Cooling system maintenance is

as important as maintenance of the fuel system and

the lubrication system. Quality of the coolant is as

important as the quality of the fuel and the lubricating

oil.

Additives must be added at the correct concentration.

Over concentration of additives can cause the

inhibitors to drop out-of-solution. The deposits can

enable the following problems to occur:

• Formation of gel compounds

Coolant is normally composed of three elements:

Water, additives and glycol.

• Reduction of heat transfer

• Leakage of the water pump seal

• Plugging of radiators, coolers, and small passages

Water

Water is used in the cooling system in order to

transfer heat.

Glycol

Distilled water or deionized water is

recommended for use in engine cooling systems.

Glycol in the coolant helps to provide protection

against the following conditions:

DO NOT use the following types of water in cooling

systems: Hard water, softened water that has been

conditioned with salt and sea water.

• Boiling

• Freezing

If distilled water or deionized water is not available,

use water with the properties that are listed in Table 4

.

• Cavitation of the water pump

Table 4

For optimum performance, Perkins recommends a

1:1 mixture of a water/glycol solution.

Acceptable Water

Property

Maximum Limit

40 mg/L

Note: Use a mixture that will provide protection

against the lowest ambient temperature.

Chloride (Cl)

Note: 100 percent pure glycol will freeze at a

temperature of −13 °C (8.6 °F).

Sulfate (SO4)

Total Hardness

Total Solids

Acidity

100 mg/L

170 mg/L

340 mg/L

pH of 5.5 to 9.0

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

SEBU9072

41

Refill Capacities

Fluid Recommendations

Most conventional antifreezes use ethylene glycol.

Propylene glycol may also be used. In a 1:1 mixture

with water, ethylene and propylene glycol provide

similar protection against freezing and boiling. Refer

to Table 5 and refer to table 6 .

NOTICE

Do not use a commercial coolant/antifreeze that only

meets the ASTM D3306 specification. This type of

coolant/antifreeze is made for light automotive

applications.

Table 5

Ethylene Glycol

Perkins recommends a 1:1 mixture of water and

glycol. This mixture of water and glycol will provide

optimum heavy-duty performance as an antifreeze.

This ratio may be increased to 1:2 water to glycol if

extra freezing protection is required.

Concentration

50 Percent

Freeze Protection

−36 °C (−33 °F)

60 Percent

−51 °C (−60 °F)

A mixture of SCA inhibitor and water is acceptable

but will not give the same level of corrosion, boiling

and, freezing protection as ELC. Perkins

recommends a 6 percent to 8 percent concentration

of SCA in those cooling systems. Distilled water or

deionized water is preferred. Standard required

ASTM D1384, D2570, and D4340

NOTICE

Do not use propylene glycol in concentrations that ex-

ceed 50 percent glycol because of the reduced heat

transfer capability of propylene glycol. Use ethylene

glycol in conditions that require additional protection

against boiling or freezing.

Table 7

Coolant Service Life

Table 6

Coolant Type

Service Life (1)

Propylene Glycol

6,000 Service Hours or Three

Years

Concentration

Freeze Protection

Perkins ELC

50 Percent

−29 °C (−20 °F)

Commercial Heavy-Duty Anti-

freeze that meets “ASTM

D6210”

3000 Service Hours or Two Year

To check the concentration of glycol in the coolant,

measure the specific gravity of the coolant.

Commercial SCA inhibitor and

Water

3000 Service Hours or One Year

Coolant Recommendations

(1)

Use the interval that occurs first. The cooling system must also

be flushed out at this time.

• ELC

• SCA

• ASTM

Extended Life Coolant

Supplement Coolant Additive

American Society for Testing and

ELC

Perkins provides ELC for use in the following

applications:

Materials

• Heavy-duty spark ignited gas engines

• Heavy-duty diesel engines

• Automotive applications

The following two coolants are used in Perkins

diesel engines:

Preferred – Perkins ELC

Acceptable – A commercial heavy-duty antifreeze

that meets “ASTM D6210” specifications

The anti-corrosion package for ELC is different from

the anti-corrosion package for other coolants. ELC is

an ethylene glycol base coolant. However, ELC

contains organic corrosion inhibitors and antifoam

agents with low amounts of nitrite. Perkins ELC has

been formulated with the correct amount of these

additives in order to provide superior corrosion

protection for all metals in engine cooling systems.

NOTICE

The 1200 and 2200 series industrial engines must

be operated with a 1:1 mixture of water and glycol.

This concentration allows the NOx reduction sys-

tem

temperatures.

to

operate

correctly

at

high

ambient

ELC is available in a premixed cooling solution with

distilled water. ELC is a 1:1 mixture. The Premixed

ELC provides freeze protection to −36 °C (−33 °F).

The Premixed ELC is recommended for the initial fill

of the cooling system. The Premixed ELC is also

recommended for topping off the cooling system.

Containers of several sizes are available. Consult

your Perkins distributor for the part numbers.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

42

SEBU9072

Refill Capacities

Fluid Recommendations

ELC Cooling System Maintenance

NOTICE

Care must be taken to ensure that all fluids are con-

tained during performance of inspection, mainte-

nance, testing, adjusting and the repair of the

product. Be prepared to collect the fluid with suitable

containers before opening any compartment or disas-

sembling any component containing fluids.

Correct additions to the Extended Life

Coolant

NOTICE

Use only Perkins products for pre-mixed or concen-

trated coolants.

Dispose of all fluids according to local regulations and

mandates.

Mixing Extended Life Coolant with other products re-

duces the Extended Life Coolant service life. Failure

to follow the recommendations can reduce cooling

system components life unless appropriate corrective

action is performed.

1. Drain the coolant into a suitable container.

2. Dispose of the coolant according to local

regulations.

In order to maintain the correct balance between the

antifreeze and the additives, you must maintain the

recommended concentration of ELC. Lowering the

proportion of antifreeze lowers the proportion of

additive. Lowering the ability of the coolant to protect

the system will form pitting, from cavitation, from

erosion, and from deposits.

3. Fill the cooling system with a 33 percent solution of

Perkins ELC and operate the engine, ensure that

the thermostat opens. Stop the engine and allow

the engine to cool. Drain the coolant.

Note: Use distilled or deionized water in the solution.

4. Again, fill the cooling system with a 33 percent

solution of Perkins ELC and operate the engine

ensure that the thermostat opens. Stop the engine

and allow to cool.

NOTICE

Do not use a conventional coolant to top-off a cooling

system that is filled with Extended Life Coolant (ELC).

Do not use standard supplemental coolant additive

(SCA).

5. Drain the drain the cooling system.

When using Perkins ELC, do not use standard SCA's

or SCA filters.

NOTICE

Incorrect or incomplete flushing of the cooling system

can result in damage to copper and other metal

components.

ELC Cooling System Cleaning

Note: If the cooling system is already using ELC,

cleaning agents are not required to be used at the

specified coolant change interval. Cleaning agents

are only required if the system has been

contaminated by the addition of some other type of

coolant or by cooling system damage.

6. Fill the cooling system with the Perkins Premixed

ELC. Operate the engine. Ensure that all coolant

valves open then stop the engine. When cool

check the coolant level.

ELC Cooling System Contamination

Clean water is the only cleaning agent that is required

when ELC is drained from the cooling system.

NOTICE

Before the cooling system is filled, the heater control

(if equipped) must be set to the HOT position. Refer

to the OEM in order to set the heater control. After the

cooling system is drained and the cooling system is

refilled, operate the engine until the coolant level

reaches the normal operating temperature and until

the coolant level stabilizes. As needed, add the

coolant mixture in order to fill the system to the

specified level.

Mixing ELC with other products reduces the effective-

ness of the ELC and shortens the ELC service life.

Use only Perkins Products for premixed or concen-

trate coolants. Failure to follow these recommenda-

tions

component life.

can result in shortened cooling system

ELC cooling systems can withstand contamination to

a maximum of 10 percent of conventional heavy-duty

antifreeze or SCA. If the contamination exceeds 10

percent of the total system capacity, perform ONE of

the following procedures:

Changing to Perkins ELC

To change from heavy-duty antifreeze to the Perkins

ELC, perform the following steps:

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9072

43

Refill Capacities

Fluid Recommendations

• Drain the cooling system into a suitable container.

Dispose of the coolant according to local

regulations. Flush the system with a 5 to 10

percent solution of Perkins ELC. Fill the system

with the Perkins ELC.

Table 8

Equation For Adding The SCATo The Heavy-Duty Coolant At

The Initial Fill

V × 0.045 = X

V is the total volume of the cooling system.

• Drain a portion of the cooling system into a

suitable container according to local regulations.

Then, fill the cooling system with premixed ELC.

This procedure should lower the contamination to

less than 10 percent.

X is the amount of SCA that is required.

Table 9 is an example for using the equation that is in

Table 8 .

Table 9

• Maintain the system as a conventional Heavy-Duty

Coolant. Treat the system with an SCA. Change

the coolant at the interval that is recommended for

the conventional Heavy-Duty Coolant.

Example Of The Equation For Adding The SCATo The Heavy-

Duty Coolant At The Initial Fill

Total Volume of the

Cooling System (V)

Multiplication

Factor

Amount of SCA

that is Required (X)

Commercial Heavy-Duty Antifreeze and

SCA

15 L (4 US gal)

× 0.045

0.7 L (24 oz)

Adding The SCA to The Heavy-Duty

Coolant For Maintenance

NOTICE

Commercial Heavy-Duty Coolant which contains

Amine as part of the corrosion protection system must

not be used.

Heavy-duty antifreeze of all types REQUIRE periodic

additions of an SCA.

Test the antifreeze periodically for the concentration

of SCA. For the interval, refer to the Operation and

Maintenance Manual, “Maintenance Interval

NOTICE

Never operate an engine without water temperature

regulators in the cooling system. Water temperature

regulators help to maintain the engine coolant at the

correct operating temperature. Cooling system prob-

Schedule” (Maintenance Section). Cooling System

Supplemental Coolant Additive (SCA) Test/Add.

Additions of SCA are based on the results of the test.

The size of the cooling system determines the

amount of SCA that is needed.

lems

regulators.

can

develop

without

water

temperature

Use the equation that is in Table 10 to determine the

amount of SCA that is required, if necessary:

Check the antifreeze (glycol concentration) in order to

ensure adequate protection against boiling or

freezing. Perkins recommends the use of a

refractometer for checking the glycol concentration. A

hydrometer should not be used.

Table 10

Equation For Adding The SCATo The Heavy-Duty Coolant For

Maintenance

Perkins engine cooling systems should be tested at

500 hour intervals for the concentration of SCA.

V × 0.014 = X

V is the total volume of the cooling system.

Additions of SCA are based on the results of the test.

An SCA that is liquid may be needed at 500 hour

intervals.

X is the amount of SCA that is required.

Table 11 is an example for using the equation that is

in Table 10 .

Adding the SCA to Heavy-Duty Coolant at

the Initial Fill

Table 11

Example Of The Equation For Adding The SCATo The Heavy-

Duty Coolant For Maintenance

Use the equation that is in Table 8 to determine the

amount of SCA that is required when the cooling

system is initially filled.

Total Volume of the

Cooling System (V)

Multiplication

Factor

Amount of SCA

that is Required (X)

15 L (4 US gal)

× 0.014

0.2 L (7 oz)

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

44

SEBU9072

Refill Capacities

Fluid Recommendations

Cleaning the System of Heavy-Duty

Antifreeze

Table 12 provides a known reliable baseline in order

to judge the expected performance of distillate diesel

fuels that are derived from conventional sources.

• Clean the cooling system after used coolant is

drained or before the cooling system is filled with

new coolant.

Satisfactory engine performance is dependent on the

use of a good quality fuel. The use of a good quality

fuel will give the following results: long engine life and

acceptable exhaust emissions levels. The fuel must

meet the minimum requirements that are stated in

table 12 .

• Clean the cooling system whenever the coolant is

contaminated or whenever the coolant is foaming.

NOTICE

i06218481

Fluid Recommendations

(Fuel Recommendations)

The footnotes are a key part of the Perkins Specifica-

tion for Distillate Diesel Fuel Table. Read ALL of the

footnotes.

• Glossary

• ISO International Standards Organization

• ASTM American Society for Testing and Materials

• HFRR High Frequency Reciprocating Rig for

Lubricity testing of diesel fuels

• FAME Fatty Acid Methyl Esters

• CFRCo-ordinating Fuel Research

• LSD Low Sulfur Diesel

• ULSD Ultra Low Sulfur Diesel

• RMERape Methyl Ester

• SME Soy Methyl Ester

• EPA Environmental Protection Agency of the

United States

General Information

NOTICE

Every attempt is made to provide accurate, up-to-date

information. By use of this document you agree that

Perkins Engines Company Limited is not responsible

for errors or omissions.

NOTICE

These recommendations are subject to change with-

out notice. Contact your local Perkins distributor for

the most up-to-date recommendations.

Diesel Fuel Requirements

Perkins is not in a position to evaluate continuously

and monitor all worldwide distillate diesel fuel

specifications that are published by governments and

technological societies.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9072

45

Refill Capacities

Fluid Recommendations

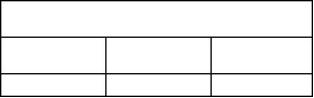

Table 12

Perkins Specification for Distillate Diesel Fuel

Property

UNITS

Requirements

“ASTM Test”

“ISO Test”

Aromatics

Ash

%Volume

%Weight

35% maximum

“D1319”

“D482”

“ISO 3837”

“ISO 6245”

0.01% maximum

Carbon Residue on 10%

Bottoms

%Weight

0.35% maximum

“D524”

“ISO 4262”

Cetane Number (1)

Cloud Point

-

40 minimum

“D613 or D6890”

“D2500”

“ISO 5165”

“ISO 3015”

°C

The cloud point must not ex-

ceed the lowest expected

ambient temperature.

Copper Strip Corrosion

Distillation

-

No. 3 maximum

“D130”

“D86”

“ISO 2160”

“ISO 3405”

°C

10% at 282 °C (539.6 °F)

maximum

90% at 360 °C (680 °F)

maximum

Density at 15 °C (59 °F)(2) Kg / M

3

800 minimum and 860

maximum

No equivalent test

“ISO 3675” or “ISO 12185”

Flash Point

°C

-

legal limit

“D93”

“ISO 2719”

Thermal Stability

Minimum of 80% reflectance

after aging for 180 minutes

at 150 °C (302 °F)

“D6468”

No equivalent test

Pour Point

°C

6 °C (10°F)

“D97”

“ISO 3016”

Minimum below ambient

temperature

Sulfur

%mass

(3)

“D5453 or /D26222”

“D445”

“ISO 20846” or “ISO 20884”

“ISO 3405”

Kinematic Viscosity (4)

2

“MM /S (cSt)”

The viscosity of the fuel that

is delivered to the fuel injec-

tion pump. “1.4 minimum

and /4.5 maximum”

Water and sediment

Water

% weight

% weight

% weight

mg/100mL

mm

0.05% maximum

“D1796”

“D1744”

“D473”

“D381”

“D6079”

“ISO 3734”

0.05% maximum

No equivalent test

“ISO 3735”

Sediment

0.05% maximum

Gums and Resins(5)

10 mg per 100 mL maximum

0.46 maximum

“ISO 6246”

Lubricity corrected wear

“ISO 12156-1”

scar diameter at 60 °C

(140 °F). (6)

Fuel cleanliness (7)

-

“ISO”18/16/13

“7619”

“ISO 4406”

(1)

In order to insure minimum cetane number of 40 a distillate diesel fuel should have minimum cetane index of 44 when ASTM D4737 test meth-

od is used. A fuel with a higher cetane number is recommended in order to operate at a higher altitude or in cold weather.

Density range allowed includes summer and winter diesel fuel grades. Fuel density varies depending on the sulfur level where high sulfur fuels

have higher densities. Some unblended alternative fuels have lower densities which are acceptable, if all the other properties meet this

specification.

(2)

(3)

Regional regulations, national regulations, or international regulations can require a fuel with a specific sulfur limit. Consult all applicable regu-

lations before selecting a fuel for a given engine application. LSD fuel with less than 0.05 percent (≤ 500 ppm (mg/kg)) sulfur is strongly recom-

mended for use in these engine models. Diesel fuel with more than 0.05 percent (≥ 500 ppm (mg/kg)) sulphur can be used only where allowed

by legislation. Fuel sulfur levels affect exhaust emissions. High sulfur fuels also increase the potential for corrosion of internal components.

Fuel sulfur levels above 0.05% may significantly shorten the oil change interval. For additional information, refer to General lubricant

Information.

(continued)

This document has been printed from SPI2. NOT FOR RESALE

![]()

46

SEBU9072

Refill Capacities

Fluid Recommendations

(Table 12, contd)

(4)

The values of the fuel viscosity are the values as the fuel is delivered to the fuel injection pumps. Fuel should also meet the minimum viscosity

requirementand the fuel should meet the maximum viscosity requirements at 40° C (104° F) of either the "ASTM D445" test method or the

"ISO 3104" test method. If a fuel with a low viscosity is used, cooling of the fuel may be required to maintain 1.4 cSt or great, er viscosity at the

fuel injection pump. Fuels with a high viscosity might require fuel heaters in order to lower the viscosity to 4.5 cSt at the fuel injection pump.

Follow the test conditions and procedures for gasoline (motor).

The lubricity of a fuel is a concern with low sulfur and ultra low sulfur fuel. To determine the lubricity of the fuel, use the “ISO 12156-1 or ASTM

D6079 High Frequency Reciprocating Rig (HFRR)” test. If the lubricity of a fuel does not meet the minimum requirements, consult your fuel

supplier. Do not treat the fuel without consulting the fuel supplier. Some additives are not compatible. These additives can cause problems in

the fuel system.

(5)

(6)

(7)

Recommended cleanliness level for fuel as dispensed into machine or engine fuel tank is "ISO 18/16/13 or cleaner as per ISO 4406. Refer to

the "Contamination Control Recommendations for Fuels" in this chapter.

Viscosity

NOTICE

Operating with fuels that do not meet the Perkins rec-

ommendations can cause the following effects: Start-

ing difficulty, poor combustion, deposits in the fuel

injectors, reduced service life of the fuel system, de-

posits in the combustion chamber and reduced serv-

ice life of the engine.

Viscosity is the property of a liquid of offering

resistance to shear or flow. Viscosity decreases with

increasing temperature. This decrease in viscosity

follows a logarithmic relationship for normal fossil

fuel. The common reference is to kinematic viscosity.

Kinematic viscosity is the quotient of the dynamic

viscosity that is divided by the density. The

determination of kinematic viscosity is normally by

readings from gravity flow viscometers at standard

temperatures. Refer to “ISO 3104” for the test

method.

Engines that are manufactured by Perkins are certi-

fied with the fuel that is prescribed by the United

States Environmental Protection Agency. Engines

that are manufactured by Perkins are certified with

the fuel that is prescribed by the European Certifica-

tion and other regulatory agencies. Perkins does not

certify diesel engines on any other fuel.

The viscosity of the fuel is significant because fuel

serves as a lubricant for the fuel system components.

Fuel must have sufficient viscosity in order to

lubricate the fuel system in both cold temperatures

and hot temperatures. If the kinematic viscosity of the

fuel is lower than 1.4 cSt at the fuel injection pump,

damage to the fuel injection pump can occur. This

damage can be excessive scuffing and seizure. Low

viscosity may lead to difficult hot restarting, stalling,

and loss of performance. High viscosity may result in

seizure of the pump.

Note: The owner and the operator of the engine has

the responsibility of using the fuel that is prescribed

by the Environmental Protection Agency (EPA) and

other appropriate regulatory agencies.

Diesel Fuel Characteristics

Perkins Recommendations

Perkins recommends kinematic viscosities of 1.4 and

4.5 cSt that is delivered to the fuel injection pump. If a

fuel with a low viscosity is used, cooling of the fuel

may be required to maintain 1.4 cSt or greater

Cetane Number

Fuel that has a high cetane number will give a shorter

ignition delay. A high cetane number will produce a

better ignition quality. Cetane numbers are derived for

fuels against proportions of cetane and

viscosity at the fuel injection pump. Fuels with a high

viscosity might require fuel heaters in order to lower

the viscosity to 4.5 cSt at the fuel injection pump.

heptamethylnonane in the standard CFR engine.

Refer to “ISO 5165” for the test method.

Density

Cetane numbers in excess of 45 are normally

expected from current diesel fuel. However, a cetane

number of 40 may be experienced in some territories.

The United States of America is one of the territories

that can have a low cetane value. A minimum cetane

value of 40 is required during average starting

conditions. A higher cetane value may be required for

operations at high altitudes or in cold-weather

operations.

Density is the mass of the fuel per unit volume at a

specific temperature. This parameter has a direct

influence on engine performance and a direct

influence on emissions. This influence determines the

heat output from a given injected volume of fuel. This

parameter is quoted in the following kg/m3 at 15 °C

(59 °F).

Perkins recommends a value of density of 841 kg/m3

in order to obtain the correct power output. Lighter

fuels are acceptable but these fuels will not produce

the rated power.

Fuel with a low cetane number can be the root cause

of problems during cold start.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

SEBU9072

47

Refill Capacities

Fluid Recommendations

Sulfur

In case of the fuels which do not meet specified

lubricity requirement appropriate lubricity additive can

be used to enhance the lubricity of the fuel.

21820275 Perkins Diesel Fuel Conditioner is the

approved additive refer to “Perkins Diesel Fuel

Conditioner”.

The level of sulfur is governed by emissions

legislations. Regional regulation, national regulations,

or international regulations can require a fuel with a

specific sulfur limit. The sulfur content of the fuel and

the fuel quality must comply with all existing local

regulations for emissions.

Contact your fuel supplier for those circumstances

when fuel additives are required. Your fuel supplier

can make recommendations for additives to use and

for the proper level of treatment.

LSD fuel with less than 0.05 percent (≤ 500 ppm (mg/

kg)) sulfur is strongly recommended for use in these

engine models.

Distillation

ULSD less than 0.0015% (≤15 PPM (mg/Kg)) sulphur

is acceptable to use in these engine models. The

lubricity of these fuels must not exceed wear scar

diameter of 0.46 mm (0.01811 inch) as per “ISO

12156-1”. Refer to “Lubricity” for more information.

Distillation will give an indication of the mixture of

different hydrocarbons in the fuel. A high ratio of light

weight hydrocarbons can affect the characteristics of

combustion.

Fuels with sulphur content higher than 0.05 percent

(500 PPM) can be used where allowed by legislation.

Classificationof the Fuels

Diesel engines have an ability to burn wide variety of

fuels. Below is a list of typically encountered fuel

specifications that have been assessed as to their

acceptability and are divided into following

categories:

Fuel with a high sulfur content can cause engine

wear. High sulfur fuel will have a negative impact on

emissions of particulates. High sulfur fuel can be

used if the local emissions legislation will allow the

use. High sulfur fuel can be used in countries that do

not regulate emissions.

Group 1: Preferred Fuels

When only high sulfur fuels are available, it will be

necessary that high alkaline lubricating oil is used in

the engine or that the lubricating oil change interval is

reduced. Refer to Operation and Maintenance

Manual, “Fluid Recommendations (Lubricant

Information)”for information on sulfur in fuel.

The following fuel specifications are considered

acceptable.

• Fuels that meet the requirements that are listed in

the table 12 .

Lubricity

•

•

•

“EN590 - Grades A to F and class 0 to 4”

“ASTM D975 Grade No. 1-D and 2-D”

Lubricity is the capability of the fuel to prevent pump

wear. The lubricity of the fluid describes the ability of

the fluid to reduce the friction between surfaces that

are under load. This ability reduces the damage that

is caused by friction. Fuel injection systems rely on

the lubricating properties of the fuel. Until fuel sulfur

limits were mandated, the lubricity of the fuel was

believed to be a function of fuel viscosity.

“JIS K2204 Grades 1, 2 & 3 & Special Grade 3”

acceptable provided lubricity ware scar diameter

does not exceed of 0.46 mm (0.01811 inch) as per

“ISO 12156-1” .

•

“BS2869 - Class A2 Off Highway Gas Oil, Red

Diesel”

The lubricity has particular significance to the current

low viscosity fuel, low sulfur fuel, and low aromatic

fossil fuel. These fuels are made in order to meet

stringent exhaust emissions.

Note: The lubricity of these fuels must not exceed

wear scar diameter of 0.46 mm (0.01811 inch) as per

“ISO 12156-1” . Refer to “Lubricity”.

The lubricity of these fuels must not exceed wear scar

diameter of 0.46 mm (0.01811 inch). The fuel lubricity

test must be performed on an HFRR, operated at

60 °C (140 °F). Refer to “ISO 12156-1”.

Group 2: Aviation Kerosene Fuels

Following kerosene and jet fuel specifications are

acceptable alternative fuels, and may be used on a

contingency base for emergency or continuous use,

where standard diesel fuel is not available and where

legislation allows their use:

NOTICE

The fuels system has been qualified with fuel having

lubricity up to 0.46 mm (0.01811 inch)wear scar di-

ameter as tested by “ISO 12156-1”. Fuel with higher

wear scar diameter than 0.46 mm (0.01811 inch) will

lead to reduced service life and premature failure of

the fuel system.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

48

SEBU9072

Refill Capacities

Fluid Recommendations

•

•

•

•

•

•

•

“MIL-DTL-83133 NATO F34 (JP-8)”

“MIL-DTL-83133 NATO F35”

“MIL-DTL-5624 NATO F44 (JP-5)”

“MIL-DTL-38219 (USAF) (JP7)”

“NATO XF63”

Raw pressed vegetable oils are NOTacceptable for

use as a fuel in any concentration in compression

engines. Without esterification, these oils may gel in

the crankcase and the fuel tank. These fuels may not

be compatible with many of the elastomers that are

used in engines that are manufactured today. In

original forms, these oils are not suitable for use as a

fuel in compression engines. Alternate base stocks

for biodiesel may include animal tallow, waste

cooking oils, or various other feedstocks. In order to

use any of the products that are listed as fuel, the oil

must be esterified.

“ASTM D1655 JETA”

“ASTM D1655 JETA1”

Fuel made of 100 percent FAME is generally referred

to as B100 biodiesel or neat biodiesel.

NOTICE

These fuels are only acceptable when used with ap-

propriate lubricity additive and must meet minimum

requirements that are listed in table 12 . The lubricity

of these fuels must not exceed wear scar diameter of

0.46 mm (0.01811 inch) as per “ISO 12156-1” . Refer

to “Lubricity” and Perkins Diesel Fuel Conditioner.

Biodiesel can be blended with distillate diesel fuel.

The blends can be used as fuel. The most commonly

available biodiesel blends are B5, which is 5 percent

biodiesel and 95 percent distillate diesel fuel. B20,

which is 20 percent biodiesel and 80 percent distillate

diesel fuel.

Note: The percentages given are volume-based. The

U.S. distillate diesel fuel specification “ASTM D975-

09a” includes up to B5 (5 percent) biodiesel.

Note: Minimum cetane number of 40 is

recommended otherwise cold starting problems or

light load misfire might occur. Since jet fuel

specifications do not mention cetane requirements,

Perkins recommends that a fuel sample is taken to

determine the cetane number.

European distillate diesel fuel specification

“EN590:2010” includes up B7 (7 percent) biodiesel.

Note: Engines that are manufactured by Perkins are

certified by use of the prescribed Environmental

Protection Agency (EPA) and European Certification

fuels. Perkins does not certify engines on any other

fuel. The user of the engine has the responsibility of

using the correct fuel that is recommended by the

manufacturer and allowed by the EPA and other

appropriate regulatory agencies.

Note: Fuels must have minimum viscosity of 1.4 cSt

delivered to the fuel injection pump. Cooling of the

fuel may be required to maintain 1.4 cSt or greater

viscosity at the fuel injection pump. Perkins

recommends that the actual viscosity of the fuel, be

measured in order to determine if a fuel cooler is

needed. Refer to “Viscosity”.

Note: Rated power loss of up to 10 percent is

possible due to lower density and lower viscosity of

jet fuels compared to diesel fuels.

SpecificationRequirements

The neat biodiesel must conform to “EN14214” or

“ASTM D6751” (in the USA) and can only be blended

in mixture of up to 20 percent, by volume in

acceptable mineral diesel fuel meeting requirements

that are listed in table 12 or the latest edition of

“EN590” and “ASTM D 975” commercial standards.

This blend is commonly known as B20.

Biodiesel Fuel

Biodiesel is a fuel that can be defined as mono-alkyl

esters of fatty acids. Biodiesel is a fuel that can be

made from various feedstock. The most commonly

available biodiesel in Europe is Rape Methyl Ester

(REM). This biodiesel is derived from rapeseed oil.

Soy Methyl Ester (SME) is the most common

biodiesel in the United States. This biodiesel is

derived from soybean oil. Soybean oil or rapeseed oil

are the primary feedstocks. These fuels are together

known as Fatty Acid Methyl Esters (FAME).

Biodiesel blends are denoted as “BXX” with “XX”

representing the content of neat biodiesel contained

in the blend with mineral diesel fuel (for example B5,

B10, B20).

In United States Biodiesel blends of B6 to B20 must

meet the requirements listed in the latest edition of

“ASTM D7467” (B6 to B20) and must be of an API

gravity of 30-45.

In North America biodiesel and biodiesel blends must

be purchased from the BQ-9000 accredited

producers and BQ-9000 certified distributors.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

SEBU9072

49

Refill Capacities

Fluid Recommendations

In other areas of the world, the use of biodiesel that is

BQ-9000 accredited and certified, or that is

accredited and certified by a comparable biodiesel

quality body to meet similar biodiesel quality

standards is required.

Perkins T400012 Fuel Cleaner is most effective in

cleaning and preventing the formation of deposits.

Refer to “Perkins Diesel Fuel System Cleaner” for

more information. Perkins UMK8276 Diesel Fuel

Conditioner helps to limit deposit issues by improving

the stability of biodiesel while also hindering the

production of new deposits. For more information

refer to “Perkins Diesel Fuel Conditioner”. Therefore

the use of Diesel Fuel Cleaner and or Diesel Fuel

Conditioner is strongly recommended when running

biodiesel blends, especially B20.

Engine Service Requirements with B20

Aggressive properties of biodiesel fuel may cause

debris in the fuel tank and fuel lines. The aggressive

properties of biodiesel will clean the fuel tank and fuel

lines. This cleaning of the fuel system can

prematurely block of the fuel filters. Perkins

recommends that after the initial usage of B20

biodiesel blended fuel the fuel filters must be replaced

at 50 hours.

General Requirements

Biodiesel has poor oxidation stability, which can result

in long-term problems in the storage of biodiesel.

Biodiesel fuel should be used within 6 months of

manufacture. Equipment should not be stored with

the B20 biodiesel blends in the fuel system for longer

than 3 months.

Glycerides present in biodiesel fuel will also cause

fuel filters to become blocked more quickly. Therefore

the regular service interval should be reduced to 250

hours.

Due to poor oxidation stability and other potential

issues, Perkins strongly recommends that engines

with limited operational time either do not use

biodiesel blends or, while accepting some risk, limit

biodiesel blend to a maximum of B5. Examples of

applications that should limit the use of biodiesel are

the following: Standby generator sets and certain

emergency vehicles.

When biodiesel fuel is used, crank case oil and

aftertreatmentsystems (if installed) may be

influenced. This influence is due to the chemical

composition and characteristics of biodiesel fuel,

such as density and volatility, and to chemical

contaminants that can be present in this fuel, such as

alkali and alkaline metals (sodium, potassium,

calcium, and magnesium).

If biodiesel must be used, then the quality of the fuel

needs to be periodically tested. The test must comply

with “EN15751”, commonly known as the Rancimat

Test.

• Crankcase oil fuel dilution can be higher when

biodiesel or biodiesel blends are used. This

increased level of fuel dilution when using

biodiesel or biodiesel blends is related to the

typically lower volatility of biodiesel. In cylinder

emissions control strategies utilized in many of the

industrial latest engine designs may lead to a

higher level of biodiesel concentration in the

engine oil pan. The long-term effect of biodiesel

concentration in crankcase oil is currently

unknown.

Perkins strongly recommends that seasonally

operated engines have the fuel systems, including

fuel tanks, flashed with conventional diesel fuel

before prolonged shutdown periods. An example of

an application that should seasonally flush the fuel

system is a combine harvester.

Microbial contamination and growth can cause

corrosion in the fuel system and premature plugging

of the fuel filter. Consult your supplier of fuel for

assistance in selecting appropriate antimicrobial

additive.

• Perkins recommends the use of oil analysis in

order to check the quality of the engine oil if

biodiesel fuel is used. Ensure that the level of

biodiesel in the fuel is noted when the oil sample is

taken.

Water accelerates microbial contamination and

growth. When biodiesel is compared to distillate fuels,

water is naturally more likely to exist in the biodiesel.

It is therefore essential to check frequently and if

necessary, drain the water separator.

Performance Related Issues with B20

Due to the lower energy content than the standard

distillate fuel B20 will cause a power loss in order of 2

to 4 percent. In addition, over time the power may

deteriorate further due to deposits in the fuel injectors.

Materials such as brass, bronze, copper, led, tin, and

zinc accelerate the oxidation process of the biodiesel

fuel. The oxidation process can cause deposits

formation therefore these materials must not be used

for fuel tanks and fuel lines.

Biodiesel and biodiesel blends are known to cause an

increase in fuel system deposits, most significant of

which are deposits within the fuel injector. These

deposits can cause a loss in power due to restricted

or modified fuel injection or cause other functional

issues associated with these deposits.

This document has been printed from SPI2. NOT FOR RESALE

![]()

50

SEBU9072

Refill Capacities

Fluid Recommendations

Fuel for Cold Weather Operation

Supplemental diesel fuel additives are not

recommended and is due to potential damage to the

fuel system or the engine. Your fuel supplier or the

fuel manufacturer will add the appropriate

supplemental diesel fuel additives.

The European standard “EN590” contains climate

dependant requirements and a range of options. The

options can be applied differently in each country.

There are five classes that are given to arctic climates

and severe winter climates. 0, 1, 2, 3 and 4.

Perkins recognizes the fact that additives may be

required in some special circumstances. Fuel

additives need to be used with caution. Contact your

fuel supplier for those circumstances when fuel

additives are required. Your fuel supplier can

recommend the appropriate fuel additive and the

correct level of treatment.

Fuel that complies with “EN590” CLASS 4 can be

used at temperatures as low as −44 °C (−47.2 °F).

Refer to “EN590” for a detailed discretion of the

physical properties of the fuel.

The diesel fuel “ASTM D975 1-D” that is used in the

United States of America may be used in cold

temperatures that are below −18 °C (−0.4 °F).

Note: For the best results, your fuel supplier should

treat the fuel when additives are required. The treated

fuel must meet the requirements that are stated in

table 12 .

In extreme cold ambient conditions, you may use the

aviation kerosene fuels that are specified in “Group 1:

Preferred Fuels”. These fuels are intended to be used

in temperatures that can be as low as −54 °C

(−65.2 °F). Refer to “Group 1: Preferred Fuels” for

detail and conditions of use of the aviation kerosene

fuels.

Perkins Diesel Fuel System Cleaner

Perkins T400012 Fuel Cleaner is the only fuel

cleaner that is recommended by Perkins .

If biodiesel or biodiesel blends of fuel are to be used,

Perkins require the use of Perkins fuel cleaner. For

more information on the use of biodiesel and

biodiesel blends refer to “Biodiesel Fuel”.

Mixing alcohol or gasoline with diesel fuel can

produce an explosive mixture in the engine crank-

case or the fuel tank. Alcohol or gasoline must

not be used in order to dilute diesel fuel. Failure

to follow this instruction may result in death or

personal injury.

Perkins fuel cleaner will remove deposits that can

form in the fuel system with the use of biodiesel and

biodiesel blends. These deposits can create a loss of

power and engine performance.

Once the fuel cleaner has been added to the fuel, the

deposits within the fuel system are removed after 30

hours of engine operation. For maximum results,

continue to use the fuel cleaner for up to 80 hours.

Perkins fuel cleaner can be used on an on-going

basis with no adverse impact on engine or fuel

system durability.

There are many other diesel fuel specifications that

are published by governments and by technological

societies. Usually, those specifications do not review

all the requirements that are addressed in table 12 .

To ensure optimum engine performance, a complete

fuel analysis should be obtained before engine

operation. The fuel analysis should include all of the

properties that are stated in the table 12 .

Detailed instructions on the rate of which the fuel

cleaner must be use are on the container.

Aftermarket Fuel Additives

Perkins Diesel Fuel Conditioner

The Perkins Diesel Fuel Conditioner part number

21820275/(U5MK8276) is the only fuel conditioner

recommended by Perkins. The diesel fuel conditioner

is a proprietary metal and ash free formulation that

has been extensively tested for use with distillate

diesel fuels for use in Perkins diesel engines. The

diesel fuel conditioner helps address many of the

challenges that various fuels worldwide present in

regards to fuel life/stability, engine startability, injector

deposits, fuel system life, and long-term engine

performance.

NOTICE

Perkins does not warrant the quality or performance

of non-Perkins fluids and filters.

When auxiliary devices, accessories, or consumables

(filters, additives) which are made by other manufac-

turers are used on Perkins products, the Perkins

warranty is not affected simply because of such use.

However, failures that result from the installation

or use of other manufacturers devices, accesso-

ries, or consumables are NOT Perkins

defects.

Therefore, the defects are NOT covered under the

Perkins warranty.

Note: Diesel fuel additives/conditioners may not

improve markedly poor diesel fuel properties enough

to make poor diesel acceptable for use.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

SEBU9072

51

Refill Capacities

Fluid Recommendations

Diesel fuel conditioner is a proven high performance,

multipurpose diesel fuel conditioner that is designed

to improve:

• Use high-quality fuels per recommended and

required specifications

• Fill fuel tanks with fuels of “ISO 18/16/13”

cleanliness level or cleaner, in particular for

engines with common rail and unit injection

systems. When you refuel the tank, filter the fuel

through a 4 µm absolute filter (Beta 4 = 75 up to

200) in order to reach the recommended

• Fuel economy (through fuel system cleanup)

• Lubricity

• Oxidation stability

cleanliness level. This filtration should be located

at the device that dispenses the fuel to the fuel

tank. In addition, filtration at the dispensing point

should remove water to ensure that fuel is

dispensed at 500 ppm water or less.

• Detergency/dispersancy

• Moisture dispersancy

• Corrosion protection

• Cetane (typically 2-3 cetane numbers)

• Perkins recommends the use of bulk fuel filter /

coalescer units which clean the fuel of both

particulate contamination and water in a single

pass.

The diesel fuel conditioner also reduces the formation

of gums, resins, and sludge, and disperses insoluble

gums.

• Ensure that you use Perkins Advanced Efficiency

Fuel Filters . Change your fuel filters per

recommended service requirements or as needed.

For maximum overall benefits, ask your fuel supplier

to add the fuel conditioner at the recommended treat

rate before fuel delivery. Or you may add the fuel

conditioner at the recommended treat rate during the

early weeks of fuel storage.

• Drain your water separators daily.

ContaminationControl

Recommendationsfor Fuels

• Drain your fuel tanks of sediment and water per

the Operation and Maintenance Manual

instructions.

Fuels of “ISO 18/16/13” cleanliness level or cleaner

as dispensed into the engine or application fuel tank

should be used. Reduce power loss, fuel system

failures, and related down time of engines will result.

This cleanliness level is important for new fuel system

designs such as common rail injection systems and

unit injection systems. Injection system designs utilize

higher fuel pressures and tight clearances between

moving parts in order to meet required stringent

emissions regulations. Peak injection pressures in

current fuel injection systems may exceed 30,000 psi.

Clearances in these systems are less than 5 µm. As a

result, particle contaminants as small as 4 µm can

cause scoring and scratching of internal pump and

injector surfaces and of injector nozzles.

• Install and maintain a properly designed bulk filter /

coalescer filtration system. Continuous bulk

filtration systems may be required to ensure that

dispensed fuel meets the cleanliness target.

Consult your Perkins distributor for availability of

bulk filtration products.

• Centrifugal filters may need to be used as a pre-

filter with fuel that is severely contaminated with

gross amounts of water and/or large particulate

contaminants. Centrifugal filters can effectively

remove large contaminants. Centrifugal filters may

not be able to remove the small abrasive particles

required to achieve the recommended “ISO”

cleanliness level. Bulk filter / coalescers are

necessary as a final filter in order to achieve the

recommended cleanliness level.

Water in the fuel causes cavitation, corrosion of fuel

system parts, and provides an environment where

microbial growth in the fuel can flourish. Other

sources of fuel contamination are soaps, gels, or

other compounds that may result from undesirable

chemical interactions in the fuels, particularly in

ULSD. Gels and other compounds can also form in

biodiesel fuel at low temperatures or if biodiesel is

stored for extended periods. The best indication of

microbial contamination, fuel additives, or cold

temperature gel is rapid filter plugging of bulk fuel

filters or application fuel filters.

• Install desiccant type breathers of 4 µm or less

absolute efficiency with the ability to remove water

on bulk storage tanks.

• Follow proper practices of fuel transportation.

Filtration from the storage tank to the application

promotes the delivery of clean fuel. Fuel filtration

can be installed at each transport stage in order to

keep the fuel clean.

In order to reduce downtime due to contamination,

follow these fuel maintenance guidelines.

• Cover, protect, and ensure cleanliness of all

connection hoses, fittings, and dispensing nozzles.

This document has been printed from SPI2. NOT FOR RESALE

![]()

52

SEBU9072

Refill Capacities

Fluid Recommendations

Consult your local Perkins distributor for additional

information on Perkins designed and produced

filtration products.

Engine Oil

Commercial Oils

i06110858

NOTICE

Fluid Recommendations

Perkins require the use of the following specifica-

tion of engine oil. Failure to use the appropriate

specification of engine oil will reduce the life of

your engine.

General Lubricant Information

Table 13

Because of government regulations regarding the

certification of exhaust emissions from the engine, the

lubricant recommendations must be followed.

Oil Specification

Preferred Oil Specification

Acceptable

• API

American Petroleum Institute

API CI-4 Plus

API CI-4

• SAE

Society Of Automotive Engineers Inc.

API CI-4 Plus meets the designed life of the product,

the use of the appropriate engine oil is essential.

Licensing

API CI-4 Plus provide two design improvements over

API CI-4 oil specification, soot viscosity control and

product shear stability.

The Engine Oil Licensing and Certification System by

the American Petroleum Institute (API). For detailed

information about this system, see the latest edition of

the “API publication No. 1509”. Engine oils that bear

the API symbol are authorized by API.

Maintenance intervals for engines that use

biodiesel – The oil change interval can be adversely

affected by the use of biodiesel. Use oil analysis in

order to monitor the condition of the engine oil. Use

oil analysis also in order to determine the oil change

interval that is optimum.

Note: These engine oils are not approved by

Perkins and these engine oils must not be used:

CC, CD, CD-2, CF-4, CG-4 and CH-4.

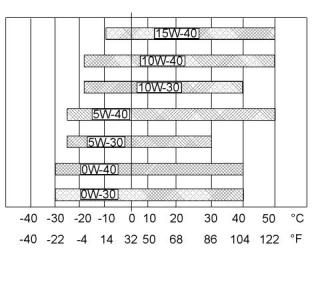

Lubricant Viscosity Recommendations

for Direct Injection (DI) Diesel Engines

The correct SAE viscosity grade of oil is determined

by the minimum ambient temperature during cold

engine start-up, and the maximum ambient

temperature during engine operation.

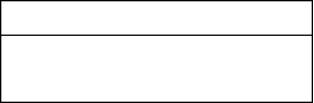

Illustration 24

g03813274

Typical API symbol

Refer to illustration 25 (minimum temperature) in

order to determine the required oil viscosity for

starting a cold engine.

Terminology

Certain abbreviations follow the nomenclature of

“SAE J754”. Some classifications follow “SAE J183”

abbreviations, and some classifications follow the

“EMA Recommended Guideline on Diesel Engine

Oil”. In addition to Perkins definitions, there are other

definitions that will be of assistance in purchasing

lubricants. Recommended oil viscosities can be

found in this publication, “Fluid Recommendations/

Engine Oil” topic (Maintenance Section).

Refer to illustration 25 (maximum temperature) in

order to select the oil viscosity for engine operation at

the highest ambient temperature that is anticipated.

Generally, use the highest oil viscosity that is

available to meet the requirement for the temperature

at start-up.

This document has been printed from SPI2. NOT FOR RESALE

![]()

![]()

![]()

![]()

![]()

![]()

![]()

SEBU9072

53

Refill Capacities

Fluid Recommendations

• See the appropriate “Lubricant Viscosities”. Refer

to the illustration 25 in order to find the correct oil

viscosity grade for your engine.

• At the specified interval, service the engine. Use

new oil and install a new oil filter.

• Perform maintenance at the intervals that are

specified in the Operation and Maintenance

Manual, “Maintenance Interval Schedule”.

Oil analysis

Some engines may be equipped with an oil sampling

valve. If oil analysis is required, the oil sampling valve

is used to obtain samples of the engine oil. The oil

analysis will complement the preventive maintenance

program.

The oil analysis is a diagnostic tool that is used to

determine oil performance and component wear

rates. Contamination can be identified and measured

by using oil analysis. The oil analysis includes the

following tests:

Illustration 25

g03329707

Lubricant Viscosities

• The Wear Rate Analysis monitors the wear of the

engines metals. The amount of wear metal and

type of wear metal that is in the oil is analyzed. The

increase in the rate of engine wear metal in the oil

is as important as the quantity of engine wear

metal in the oil.

Supplemental heat is recommended for cold soaked

starts below the minimum ambient temperature.

Supplemental heat may be required for cold soaked

starts that are above the minimum temperature that is

stated, depending on the parasitic load and other

factors. Cold soaked starts occur when the engine

has not been operated for a period of time. This

interval will allow the oil to become more viscous due

to cooler ambient temperatures.

• Tests are conducted in order to detect

contamination of the oil by water, glycol, or fuel.

Aftermarket Oil Additives

• The Oil Condition Analysis determines the loss of

the oils lubricating properties. An infrared analysis

is used to compare the properties of new oil to the

properties of the used oil sample. This analysis

allows technicians to determine the amount of

deterioration of the oil during use. This analysis

also allows technicians to verify the performance

of the oil according to the specification during the

entire oil change interval.

Perkins does not recommend the use of aftermarket

additives in oil. The use of aftermarket additives in

order to achieve the engines maximum service life or

rated performance is not necessary. Fully formulated,

finished oils consist of base oils and of commercial

additive packages. These additive packages are

blended into the base oils at precise percentages in

order to help provide finished oils with performance

characteristics that meet industry standards.

There are no industry standard tests that evaluate the

performance or the compatibility of aftermarket

additives in finished oil. Aftermarket additives may not

be compatible with the finished oils additive package,